Summary

There is a growing desire for even more customization to improve performance and efficiency in the dynamic industry of robotics and factory automation.

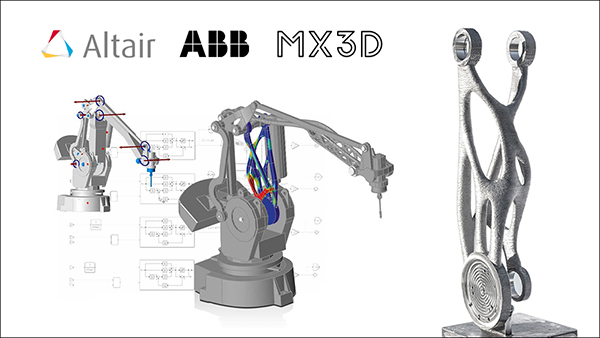

MX3D and Altair demonstrate how to apply large-scale 3D metal printing to customize manufacturing equipment and increase productivity.

Showcasing the use of Digital Twin Technology to drive system understanding for better design, higher operational efficiency and reduced implementation risks attendees will learn:

There is a growing desire for even more customization to improve performance and efficiency in the dynamic industry of robotics and factory automation.

MX3D and Altair demonstrate how to apply large-scale 3D metal printing to customize manufacturing equipment and increase productivity.

Showcasing the use of Digital Twin Technology to drive system understanding for better design, higher operational efficiency and reduced implementation risks attendees will learn:

- How to identify high-value parts and value drivers for additive manufacturing

- How to get started with large scale 3D metal printing

|

||||

| Thomas Van Glabeke has a MS in Design Engineering from Ghent University. He worked as a Project Manager at Joris Laarman Lab, exploring state-of-the-art manufacturing techniques and software technologies. Currently, he works as a R&D Engineer and Business Developer for MX3D, a large-scale 3D metal printing company. Thomas has a great passion for additive manufacturing and showcasing it’s capabilities through various projects such as the MX3D Robot Arm and MX3D’s Arc Bike II. | ||||

|

Date & Time

Thursday April 23rd, 2020 2:00pm EDT

End Date & Time

Thursday April 23rd, 2020 3:00pm EDT

Category

Webinar

Login to RSVP for Event

Login Button

Event Map