19 Posts

Dear Carol, SME Members:

Can you or members guide me to Induction and / or friction welders?

As posted earlier. My question to SME members in general was under 'A Challenge, New Science' category and also a bit cheeky but heading 'We can Weld in Space? Yes!'.

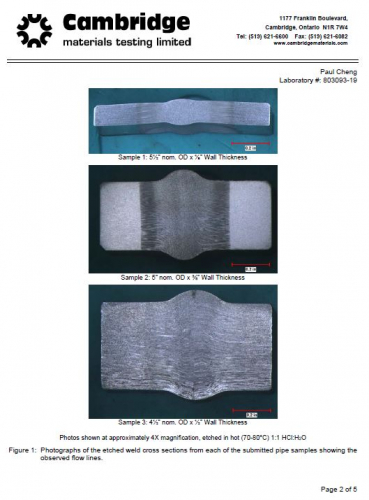

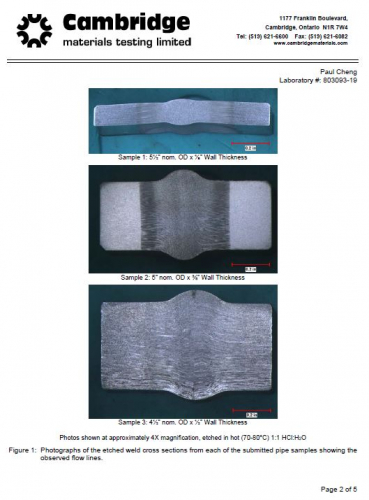

There is general knowledge w/ one singular solid state fusion i.e. to fuse both tubulars. Place one heating coil in-between work faces, heat to hot working temp, w/draw coil, forge and rotate / shear one of the tubular pieces. Result is flawless fusion weld w/ Xln structure that are Fine Grained thruout.

The problem is how do you join the last piece? Or where there is no room for rotation such as feeder tubes to manifold in nuclear reactor? My solution was to introduce a short joint in-between the two sides. Heat all work faces simultaneously, w/draw heating paddles, rotate the coupler and push both sides in. Several members contributed possible solutions.

Can you guide me or introduce me to engineers and companies who are able and willing to build high precision demo equipment in the U.S. and Canada.

Benefits are numerous especially to DOD, Navy, Nuclear, pipeline, Pharma, auto (dissimilar materials)

Sincerely

Paul Cheng

+1 519 709 2091

FuseRing.com

Member: OCNI, CWB; ANS, AWS, SME, ASNE

Can you or members guide me to Induction and / or friction welders?

As posted earlier. My question to SME members in general was under 'A Challenge, New Science' category and also a bit cheeky but heading 'We can Weld in Space? Yes!'.

There is general knowledge w/ one singular solid state fusion i.e. to fuse both tubulars. Place one heating coil in-between work faces, heat to hot working temp, w/draw coil, forge and rotate / shear one of the tubular pieces. Result is flawless fusion weld w/ Xln structure that are Fine Grained thruout.

The problem is how do you join the last piece? Or where there is no room for rotation such as feeder tubes to manifold in nuclear reactor? My solution was to introduce a short joint in-between the two sides. Heat all work faces simultaneously, w/draw heating paddles, rotate the coupler and push both sides in. Several members contributed possible solutions.

Can you guide me or introduce me to engineers and companies who are able and willing to build high precision demo equipment in the U.S. and Canada.

Benefits are numerous especially to DOD, Navy, Nuclear, pipeline, Pharma, auto (dissimilar materials)

Sincerely

Paul Cheng

+1 519 709 2091

FuseRing.com

Member: OCNI, CWB; ANS, AWS, SME, ASNE

Replies

Login or Join to Access the Knowledge and Resource Center

SME's Manufacturing Research Assistance is a valuable SME member benefit. Login (via the blue button at the top of the page) to access to specialized research assistance to help with their most pressing research needs, Q&A archives and a comprehensive resource library.

To gain full access to the Q&A and resources, login or click the Join Now button below.

Join Now!

To gain full access to the Q&A and resources, login or click the Join Now button below.